Open Galvanized Barrel Closed Galvanized Barrel

The material required for barrel making is high-quality steel, which can provide product inspection certificates, has export qualifications, and supports pre-ordered printing of logos on the barrels. The color can be customized according to customer needs. The company is equipped with trucks and can deliver goods in large quantities.

Dear user, in order to avoid unnecessary losses caused by improper selection of steel drums when you choose steel drums, please understand the following knowledge about steel drums.

1. Determination of the volume of the steel drum

a. If the user holds liquid, the calculation is based on the specific gravity of the product, but sufficient space (safe volume) of 10% of the product's thermal expansion must be left to prevent the steel drum from cracking when it falls and deforms.

b. If the user contains solids, he or she needs to ask the steel drum manufacturer to provide a steel drum of a certain volume for trial loading, and then convert it into a steel drum with a volume required by the weight. However, a certain amount of space must also be left for lining with plastic bags to prevent steel drums from being packed. The barrel will burst when dropped and deformed.

c. If the user is filling products with low boiling points (generally referring to boiling points below 60°C), they must fully consider that such products have vapor pressure at a certain temperature, and the vapor pressure of liquids increases as the temperature increases. In addition, the product filling temperature and the maximum storage and transportation temperature that the steel drum may encounter after product filling should be considered. Generally, 55°C should be considered. In some areas, the temperature difference between 60°C should be considered, which will cause the product volume to expand and lead to steel Internal pressure is generated inside the barrel. The sum of these two pressures cannot be greater than the allowable internal pressure of the steel drum, otherwise the steel drum will burst. Steel drums are allowed to withstand internal pressure. For details, please refer to the commodity inspection certificate or consult the steel drum manufacturer.

d. If the user's filling temperature is high (above 60°C), the minimum temperature for storage and transportation must be taken into consideration. The temperature difference will cause the steel drum to generate negative pressure, which will cause the steel drum to be deflated or dented when it is touched. Solution: 1. After the filled product is cooled to a certain temperature, screw on the screw plug. 2. Leave enough space.

2. The gaskets and bushings on the closure should be made of different materials according to the different products the user is loading. Users can ask the steel drum supplier to provide lining rings of different materials for a compatibility immersion test for more than one month, and then determine the swelling and deformation conditions.

3. The raw material of the steel drum is cold-rolled plate. During the rolling process of the steel factory, the thickness is slightly different. Therefore, the industry stipulates that the weight of the steel drum is limited to plus or minus 0.3 kg/barrel. In order to prevent the steel plate from rusting, the steel factory lightly coats the steel plate. Without anti-rust oil, after the barrel-making spray paint is dried, there will inevitably be an odor. Therefore, when users choose to use it, please inform the steel barrel factory in advance so that corresponding pre-treatment can be done during the barrel-making process.

Commodity inspection knowledge:

When customers use steel drums to package products for export, they should require the steel drum supplier to provide an outbound cargo transportation packaging performance inspection result sheet, referred to as a commodity inspection certificate. The relevant knowledge is as follows:

1. When customers need to apply for a commodity inspection certificate, they should provide the steel drum factory with the name of the product, product UN number, product hazard category, and transportation method.

2. When customers use steel drums for export, the products contained in the steel drums are divided into four categories according to the performance of the steel drums: dangerous goods Class I, dangerous goods Class II, dangerous goods Class III, and non-dangerous goods. Among them, X, Y, and Z correspond to dangerous goods Class I, dangerous goods Class II, and dangerous goods Class III respectively.

3. Hubei Xinyuan Cooperage Co., Ltd., the steel drum packaging category is Category I, covering other categories.

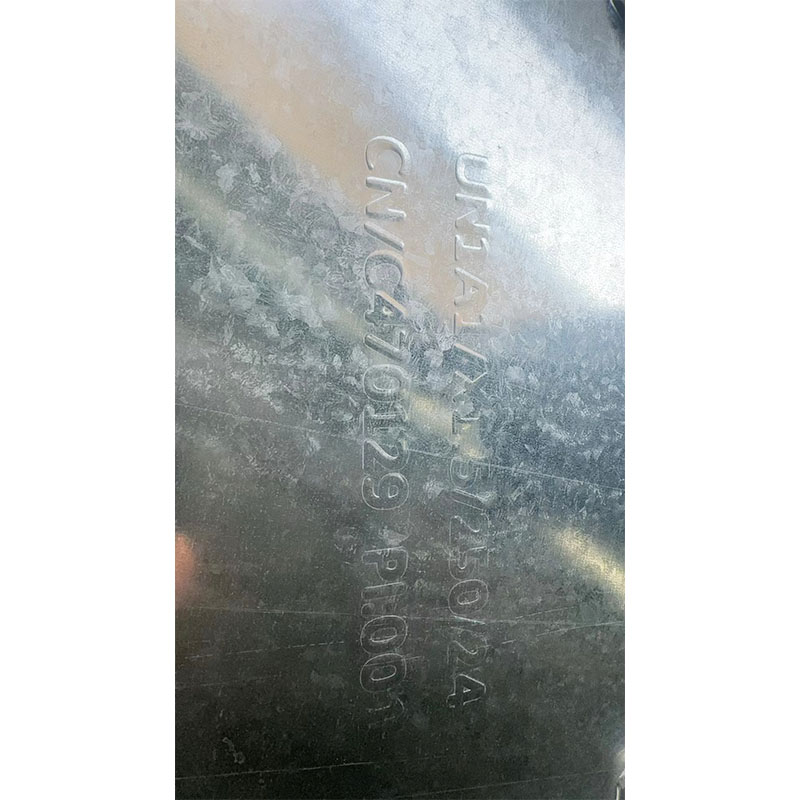

The commodity inspection stamp is: UN 1A1/X1.5/250/** CN/C470129 PI:***

4. Customers who use steel drums to package products for export generally go through the following procedures:

1) The customer and the steel drum supplier sign the "Purchase and Sales Contract".

2) Steel drum suppliers go to the local Commodity Inspection Bureau to apply for commodity inspection certificates.

3) After the customer obtains the commodity inspection certificate and steel drum, he loads the products and takes them to the local Commodity Inspection Bureau in exchange for the "Outbound Goods Transport Package"

Installation and use of identification results sheet.

4) Complete customs clearance procedures with the "Result Form of Appraisal of Outbound Goods Transport Packaging" and other relevant procedures.